DC-61 DISC

CROSS DISC Highest modulus carbon fibre monocoque frame

Highest modulus carbon fibre monocoque frame

• Carbon monocoque highest modulus mrc mr 60

• weight 1.050 g (size M)

• 4 sizes S, M, L, XL

• Bottom bracket BB86

• Inner cables routing for mechanical and electronic devices

• Seatpost 27,2 mm

• Tapered headtube 1-1/8” – 1-1/2” with integrated headset SSDIFF83

• Carbon moncoque F-61 fork weight 450 g

• Compatible hanger FRCDPP12GTC

• Front trough axle item number PP12512 - M12*P1.5*125

• Rear trough axle item number PP16512 - M12*P1.5*1

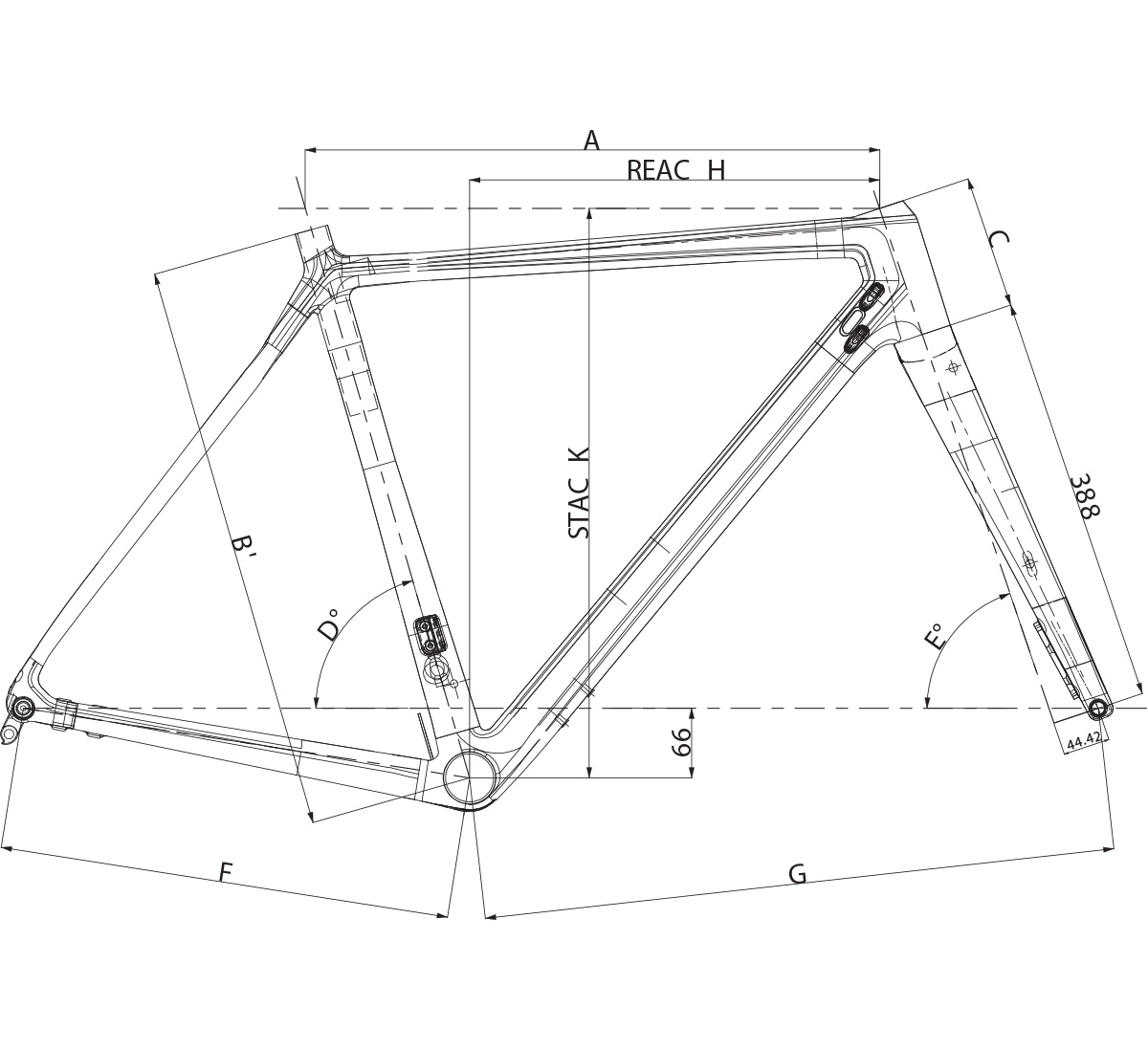

| SIZE | A | B' | C | D | E | F | G | REACH | STACK |

| S | 520 | 520 | 110 | 74.5° | 74.5° | 425 | 582 | 375 | 522 |

| M | 540 | 540 | 125 | 74° | 74° | 425 | 595 | 386 | 539 |

| L | 555 | 560 | 140 | 73.5° | 73.5° | 425 | 600 | 391 | 554 |

| XL | 575 | 580 | 150 | 73° | 73° | 425 | 605 | 397 | 566 |

English

English  Italiano

Italiano